1st – 24th August 2025

A bit of a bulk update as things have been busy and little time to keep the blog current.

Here’s a list of work done in the last three weeks or so:

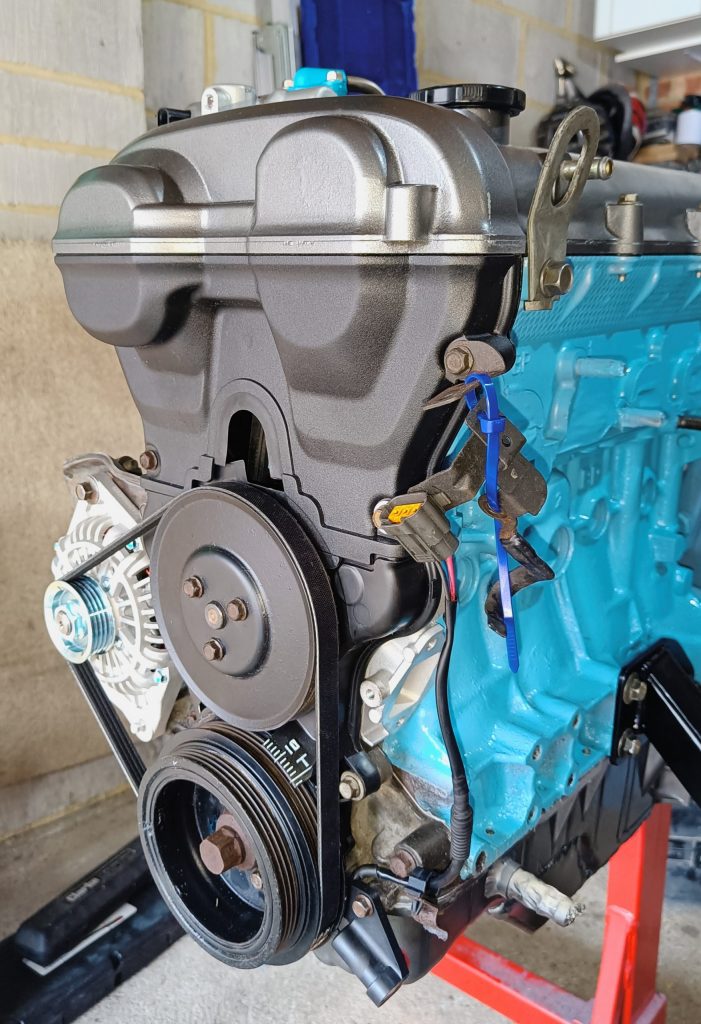

- Alternator installed and then removed / modified to increase clearance with the steering column.

- Engine mounts upgraded to firmer / taller items to help the alternator and clutch slave cylinder clearance issues.

- ECU panel painted and rivetted / bonded to chassis.

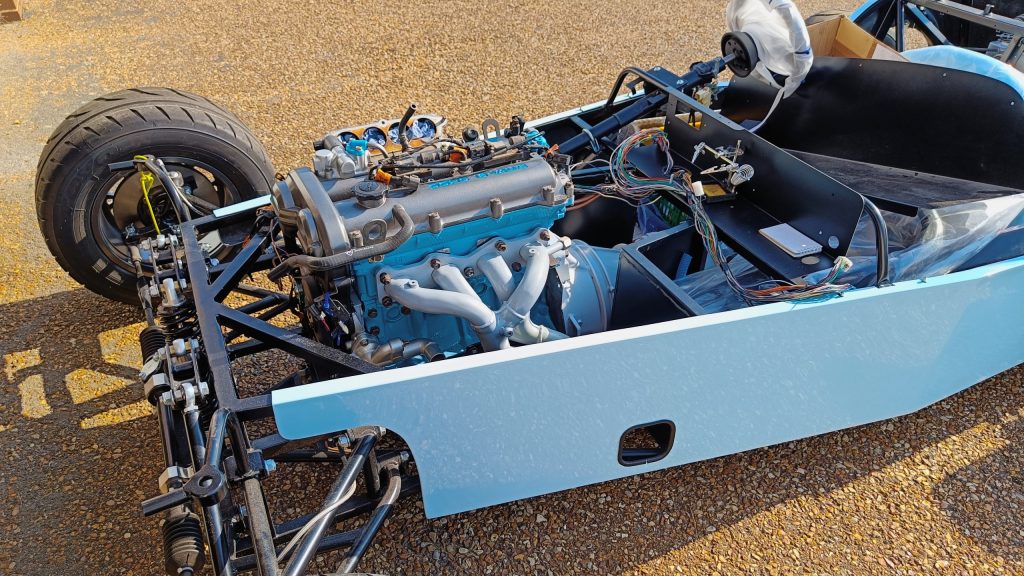

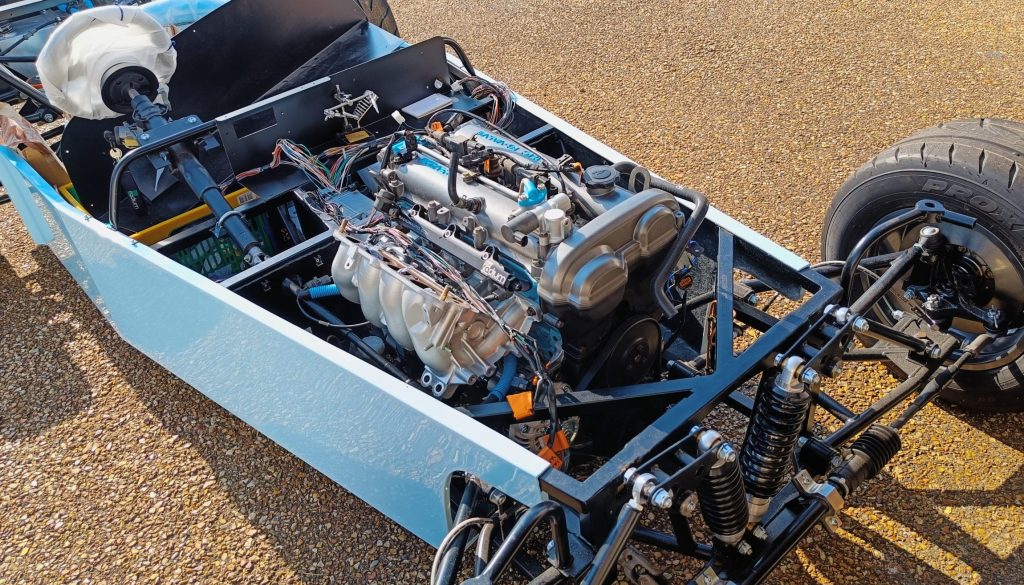

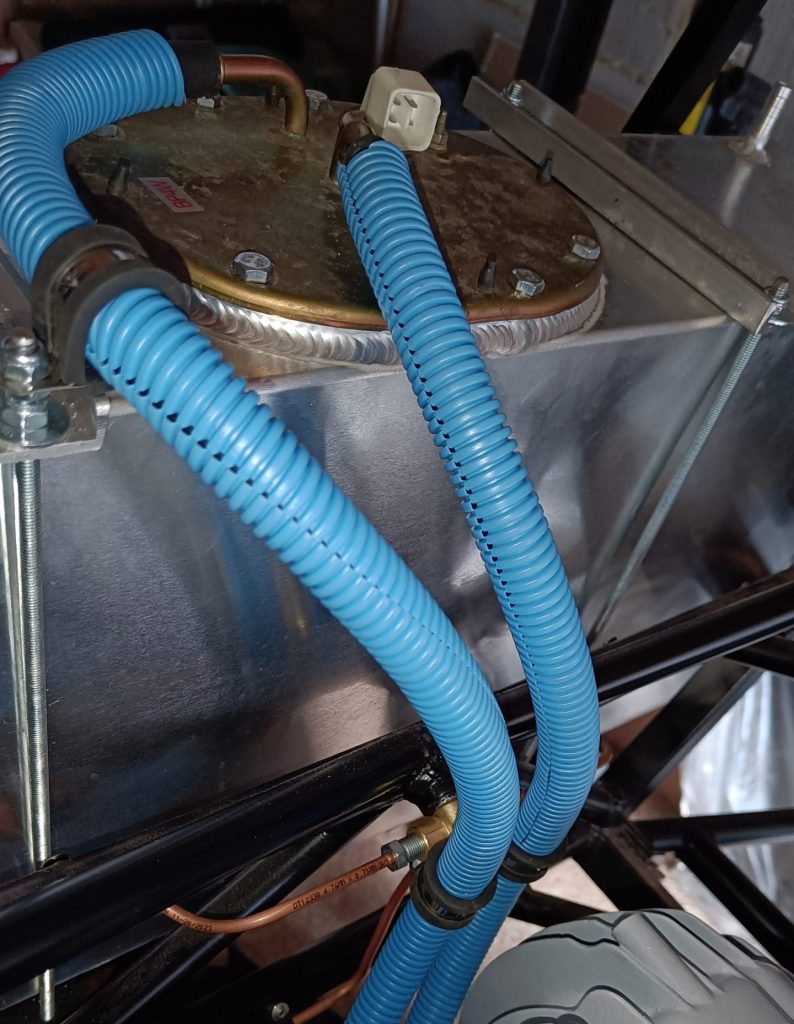

- Flexi fuel line installed under intake manifold using OEM ‘hanger’ ready to connect to fuel rail.

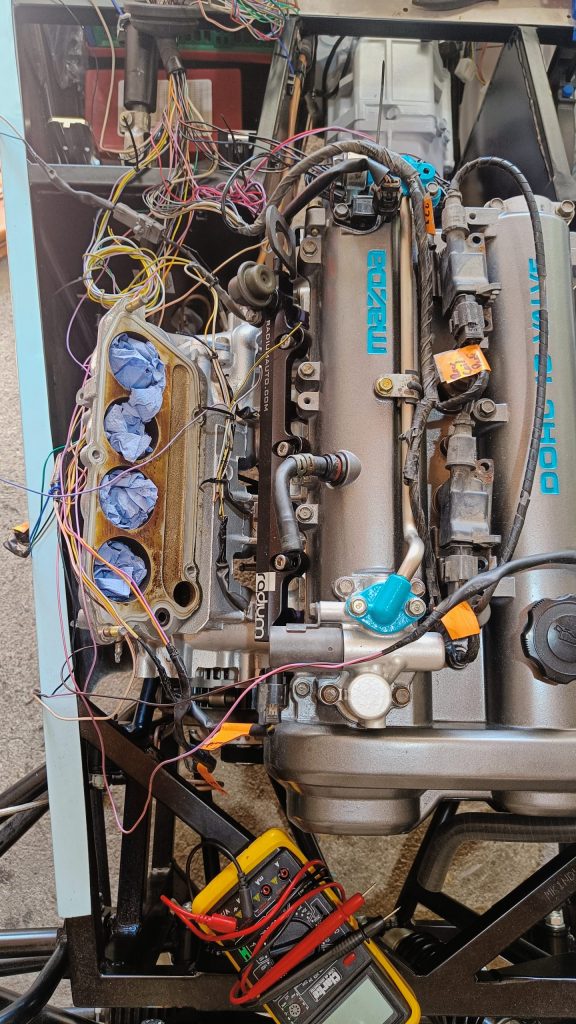

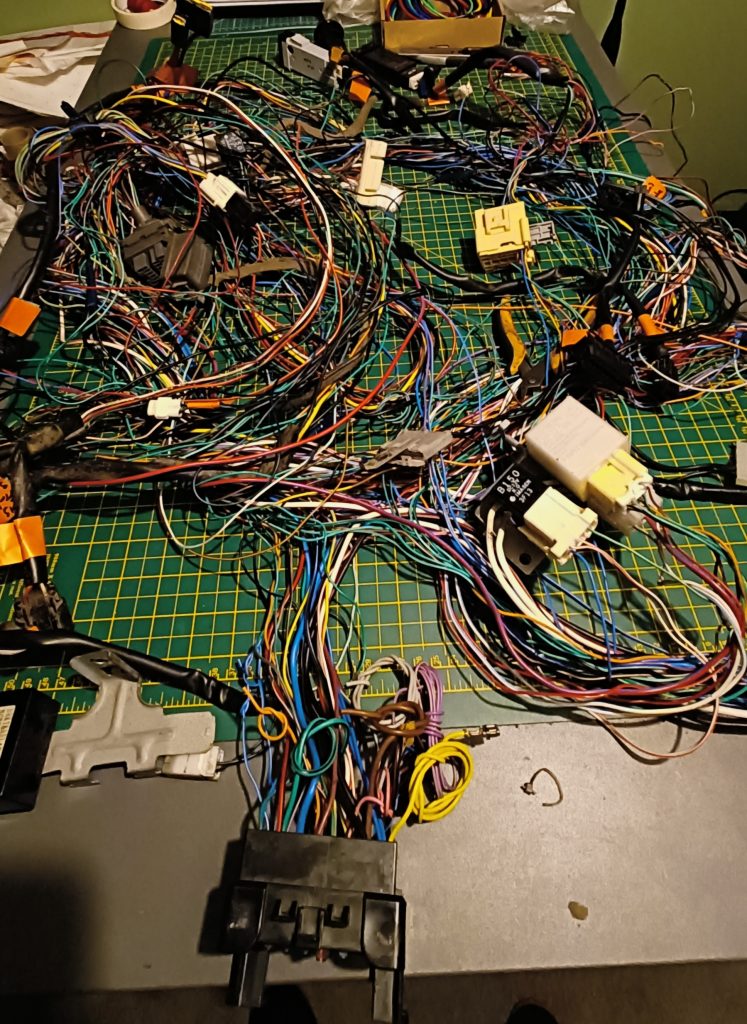

- Engine loom modified to delete the three connectors at front o/s of the engine, the EGR connector, MAF connector (MAP sensor will be fitted) and other connector wiring shortened.

- Main, front and rear looms stripped of no longer required wiring, connectors and relays.

I decided to do away with the stock rubber engine mounts and go with a set of these, which were very well made with removable studs to ease fitting:

Revshift polyurethane MX5 engine mounts.

Reason being that the original items seem to squash a little too much and along with the aftermarket alternator, I needed to resolve the rather poor clearance between the latter and the steering column (despite already grinding a little off of both the alternator casing and the oil pump pressure relief access boss).

These items are stiffer and slightly taller (~8mm). They are tad pricey once you factor in UPS shipping from Michigan, but everywhere in the UK seemed to be out of stock of similar.

Whilst fitting them I took the opportunity to nudge the engine over a little more to the nearside by putting a 2mm washer between the offside engine mount and the block, at each fixing point, and elongating the MK bracket holes where the new poly mounts bolt to.

Otherwise most of the rest of the time has been taken up with loom reduction / modifications. Having as much information as you can is highly advantageous in this task, much time spent pondering the wiring diagrams to check ‘dependencies’ before removing wiring. As I’m installing an ME221 ECU, there’s a fair bit more ‘rationalistion’ that can be done to the looms – we’ll see if that was a good idea quite soon!

Here are the pics:

The plan now is to get to first start in the next two weeks. Here’s the list that needs to be done:

- Additional rivets in ECU panel.

- Connect flexi fuel line to fuel rail input

- P clip rigid fuel lines to chassis near to front as poss.

- Connect rigid fuel lines to flexi fuel lines.

- Bracket for fuel regulator – extra long for engine loom P clip?

- Fit rubber bungs to unused coolant outlets.

- Fit ME221 into ECU box.

- Mount ECU

- Run in engine loom & wrap.

- Trim gearbox mount bolt.

- Order intake manifold gaskets and oil filter

- New exhaust manifold studs and nuts?

- Fit Lambda sensor.

- Fit exhaust pipe.

- Temp fit main fuse box and cables to alternator / starter / battery

- Temp fit main loom & connections to ignition / dash

- Tighten spark plugs

- Torque crank pulley bolt

- Fit oil filter

- Fit dip-stick

- Engine oil

- Gearbox oil (90ml in to turret and fit gearstick)

- Diff oil

- Might it start? (Program base map into ECU)